Application For Employment

Please complete this form to apply

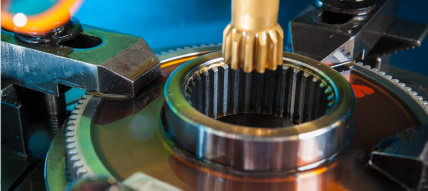

Uncompromising quality, reliability, flexibility and professionalism ensure that our customers achieve their gear production objectives with confidence. Our investments in new technologies, resources, and state-of-the-art equipment guarantee high performance, precision, optimal efficiency, and fast turnaround.

Our engineering department is equipped with powerful technology tools, including the latest SolidWorks, AutoCad, and UTS gear analysis software. Two advanced manufacturing facilities expand our production capabilities and services with a wide range of sophisticated machinery for bevel and cylindrical gear production, including in-house quality control and inspection. We manufacture any production volume, even low lot sizes built to specification, at a reasonable cost and short lead times, with a commitment to lean manufacturing processes.

Reliance Gear offers a wide range of solutions for custom gearing and non-gear machined components, specializing in precision fabrication. We work with a variety of steel and stainless-steel alloys, as well as cast iron, bronze, Pyrowear®, high temperature alloys, and plastics.

Our comprehensive range of services includes CNC grinding, CNC machining, Mil-Spec certified welding, assembly, and painting services. We work in any production volume and pride ourselves on our manufacturing versatility, striving to meet our customers’ manufacturing challenges and critical specifications.

Reliance Gear is experienced with a variety of materials including alloy steel, stainless steel, maraging steel, Pyrowear, cast iron and many plastics. Our investment in advanced CNC technology for soft machining, fine finishing and gear inspection enables us to produce gears to aircraft quality levels.

Reliance Gear Corporation manufactures custom precision Bevel Gears including Spiral Bevel, Coniflex Straight Bevel, Hypoid and Zerols. Our years of experience in gear cutting, coupled with precise manufacturing equipment, means that we can produce gears to tight tolerances that meet all AGMA Class 13 specifications. Our equipment includes Gleason bevel gear production machinery to provide Face Milling, Face Hobbing, Lapped and Ground Bevel Sets.

Part Diameter: Min: 1½ ” Max: 28”

Face Width: Max: 5.0”

Diametral Pitch: Min: Min: 32 Max: 1.8

Tolerance: AGMA 13 (Max PD 14.75” PD)

Backed by nearly 60 years of experience, Reliance Gear produces precision Parallel Axis Gears including Internal and External, Helical, Spur and Ground Tooth Gears. We are capable of grinding gears to AGMA Class 13 tolerances and use CMM Analytical Gear Inspection equipment to confirm all tolerances and dimensions.

Part Diameter: Min: ½ ” Max: 26”

Face Width: Max: 5.0”

Diametral Pitch: Min: Min: 64 Max: 2.5

Tolerance: AGMA 13 (Max PD 14.75” PD)