Our precision open gearing has earned us a sterling reputation with customers in the aerospace, defense, oil and gas, agriculture, construction, and commercial industries and are now making a name for ourselves with precision CNC Machining Services. In addition to CNC Machining and gear cutting, we offer various assembly support.

Precision CNC Grinding

Reliance Gear provides precision CNC Grinding as a complement to our Bevel Gear Manufacturing, Parallel Axis Gear Manufacturing and CNC Machining capabilities. CNC Grinding capabilities include ID, OD, and Surface Grinding in addition to Manual Thread Grinding, Taper Grinding and Bore Honing services. Our CNC Grinding capabilities allow us to provide common grinding operations with unparalleled efficiency and precision while our flexibility enables us to work with a variety of production volumes and component types.

Part Diameter: Min: 3/8” Max: 8″

Part Width: Min: 3/8” Max: 40”

Part Height: Min: 3/8” Max: 17”

Parallelism: .0002” to .0005”

Flatness: .0002” to .0005”

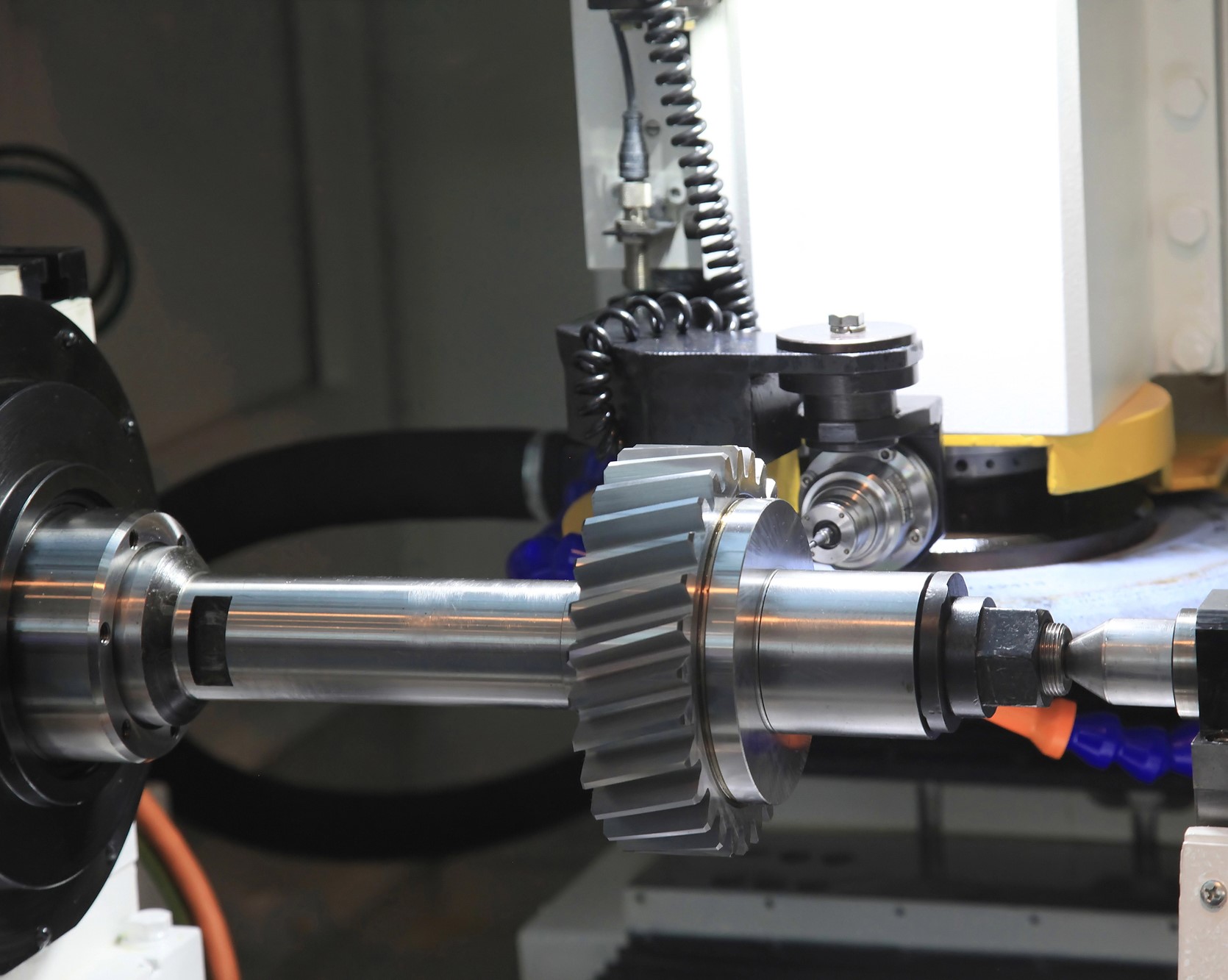

Turning & Milling

Reliance Gear has a 6S facility with full capability for turning and milling cylindrical gear blanks. Some of our core competencies are turning, threading, milling, drilling and boring. Our CNC Milling Centers and Lathes allow us to mill and turn a variety of components.

Turning:

Part Diameter: Min: ¼” Max: 23”

Part Length: Turning up to 32″, Milling up to 38″

Part Width & Height: Milling up to 18” x 18”

Weight: 1 Ton

Milling:

Part Length: Up to 32″

Part Width & Height: Milling up to 18” x 18